Process

We are a first foreign MNC handled by foreign nation in electroplating industries. As our company name says, we would like to be a new star (Crenova) created in India and pursue a hub of global electroplating industries by enhancing level of plating quality in India.

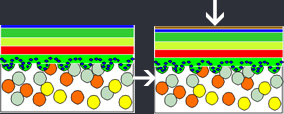

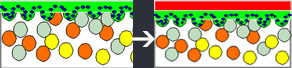

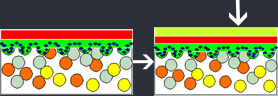

The process which make many small hole on plastic surface with Chromium sulfuric acid and which take out Butadiene to give adhesion power after plating

the process that Cr6+ reduce Cr3+ on plastic suface to protect Activation bath

Cr6+ solution

Cr3+ Solution

The process which Pd-Sn ion is absorbed into the etching hole on plastic surface then next E’less Ni can be deposited

Remove Sn ion from Pd-Sn cluster and it can make to occur following e'less nickel process

the process make conductivity on plastic surface by the deposition of e'less nickel

Ni2+ + 2e(by Reduction agent) → Nio Pd catalyst

E'less Ni

Copper plating give the brightness and the leveling effect

the process prevent corrosion that means increasing corrosion resistance

Semi Bright Nickel

the process give the brightness

Bright Nickel

the process give many pores on bright nickel

MPS Nickel

the process gives white finish and wear resistance on nickel layer

Chrome